Manufacturing

Manufacturing

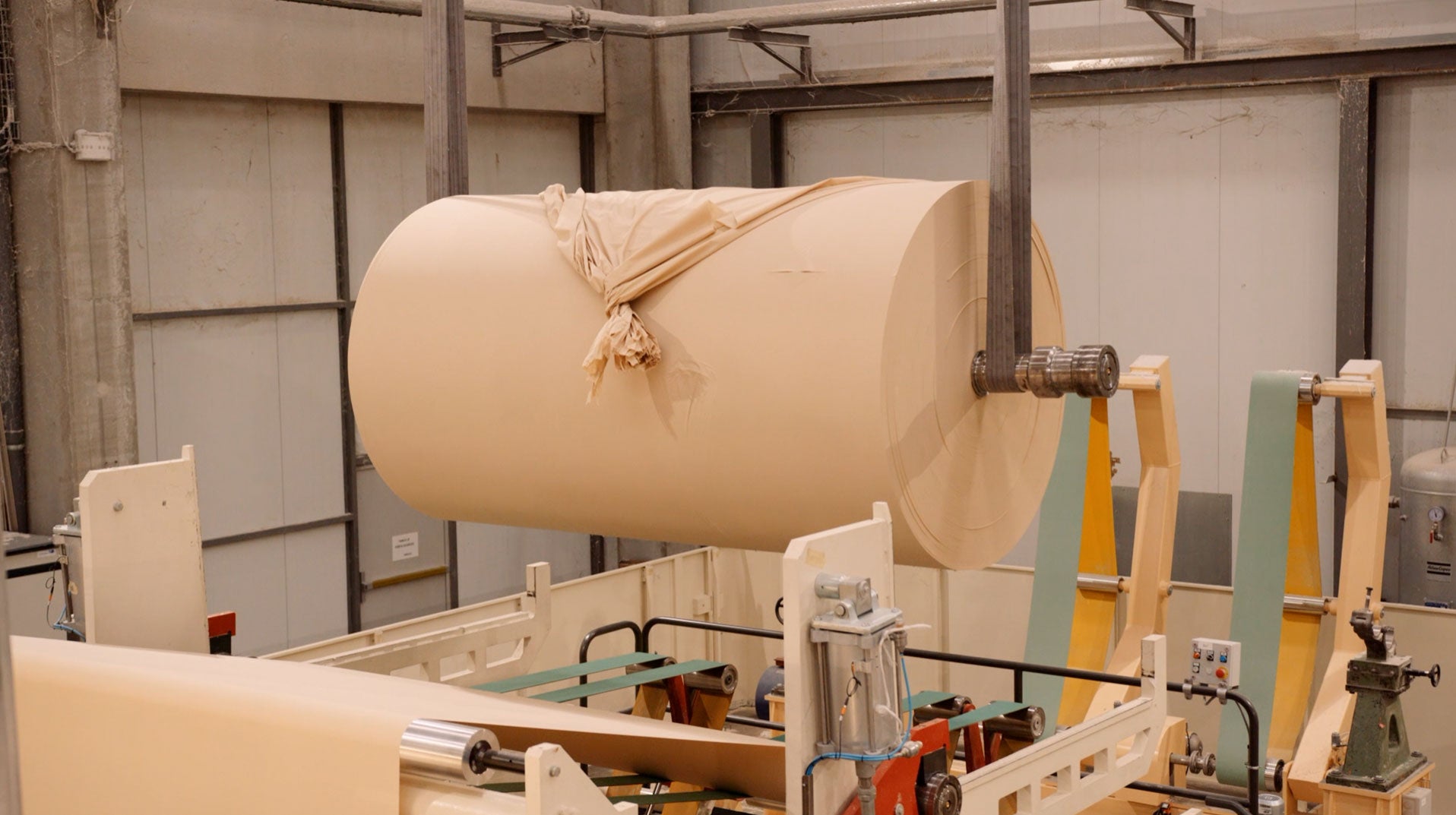

Our factory is completely fossil fuel free. It's powered by onsite renewable energy using over 8,000 solar panels, a biomass plant and a water treatment plant. No harsh chemicals are used in the production of our tissue products.